Less Out-Of-Joint Cracking

Concrete curl can be reduced, but it can't be eliminated. In addition, the curl of a slab is more pronounced in a longer slab than in a short slab that experiences the same radius of curl. The TCP system uses these principles to minimize mid-panel cracking.

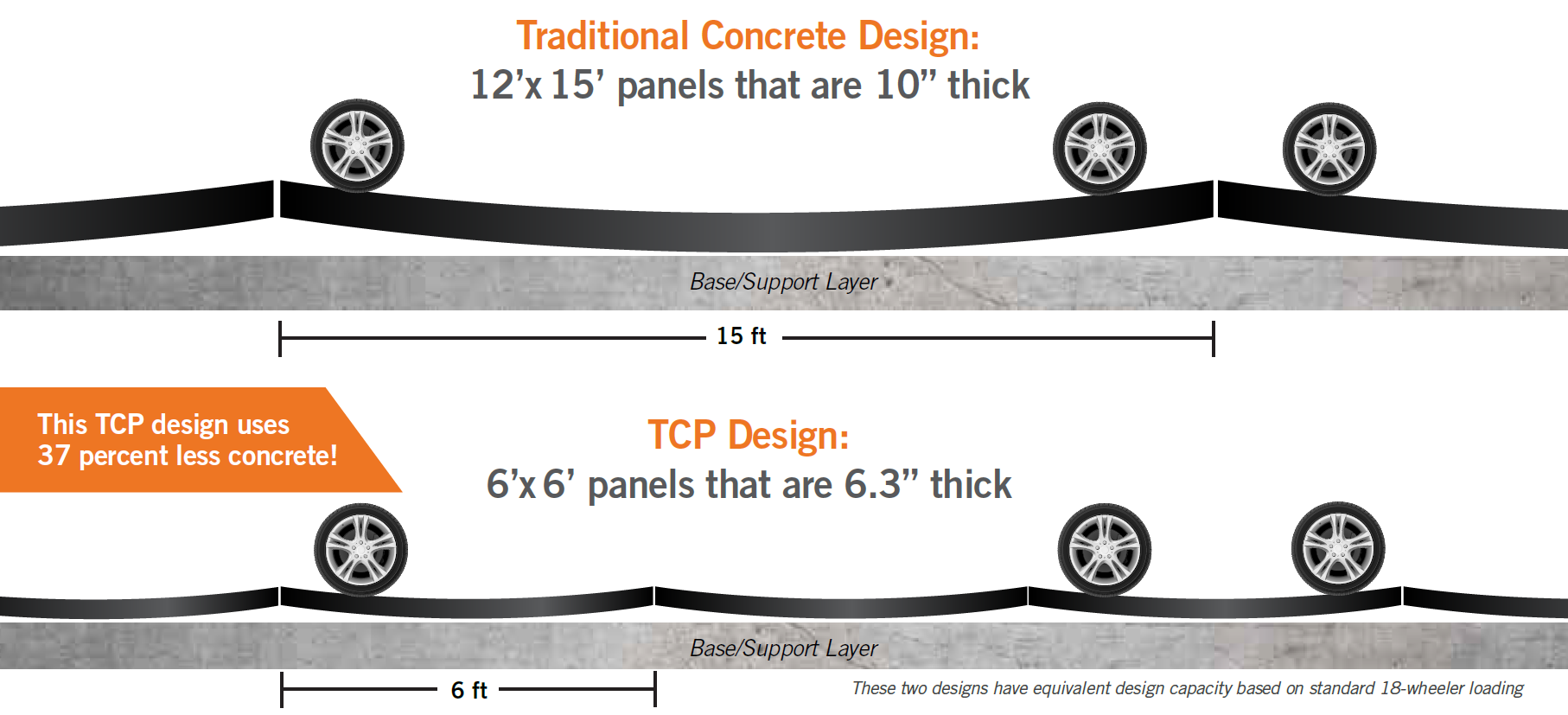

With traditional 12- to 15-foot (3.6- to 4.6-meter) panels, wheel loads apply pressure on both ends of the panel, creating stresses that cause top-down cracking in the middle. TCP minimizes these stresses by shortening the panel length to 8 feet or less. This reduces the amount of curl and prevents both edges of the panel from being loaded simultaneously. As a result, the panel experiences less stress and fewer cracks.